The Amazing Accutron Index Wheel

The Index wheel in an accutron, I believe is the most technically difficult and highest precision watch part ever made.

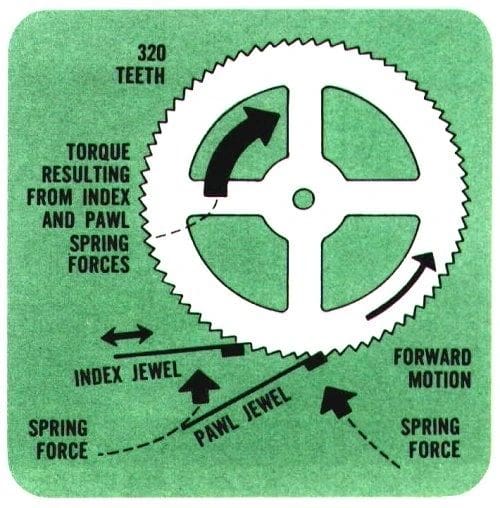

The mechanism provides the means for converting the vibrations of the tuning fork into rotary motion and is a remarkable engineering accomplishment. Though the dimensions of the working parts are incredibly small, the operation of the index mechanism is elegantly simple, and its robustness and reliability is incredible. It is very delicate and requires special handling techniques during servicing and adjustment. The index wheel can be destroyed by simply touching it on its rim; it must be handled by its pinion only. It consists of two very fine flat springs (or “fingers”), each with a small ruby jewel cemented with epoxy onto one end. One of the springs (the pawl finger) is attached to the body of the watch by a small movable carrier and post. The other (the index finger) is attached to a post mounted on one arm of the tuning fork. The jewels of each finger rest on a special ratchet wheel (the index wheel) which has very small triangular shaped teeth. These teeth are so small, they cannot be seen without the aid of a microscope and even under a 200x magnification are extremely hard to see. The positions of the index and pawl jewels relative to each other is adjusted by moving the pawl jewel carrier

Correct adjustment is necessary to allow for variations in fork amplitude during the life of the battery. This is known as “phasing” the index mechanism, and requires good watchmaking skills, experience on Accutrons, and a good understanding of the operation of the index mechanism to be carried out correctly. In operation, when the fork moves towards the index wheel, the index jewel pushes the wheel around slightly more than one tooth. The wheel is then locked in place by the pawl jewel, so when the fork and index jewel moves back, the index wheel stays stationary. This occurs once for every vibration of the fork, or 360 times per second for a 214 or 218 Accutron movement. The index wheel of a 218 movement is 2.40mm (0.095″) in diameter and has 320 teeth, each of which is about 0.01mm high (0.0004″) and 0.02mm (0.0008″) wide. The index and pawl jewels are perfect little square blocks of synthetic ruby, 0.18mm (0.007″) square and 0.06mm (0.002) thick. How these parts were manufactured has remained a closely-guarded secret and to this day no one has been able to understand or explain the process to me.

Each cycle of vibration of the tuning fork causes the index wheel to advance 1 1/2 teeth, then “draw” back 1/2 a tooth for a net advance of exactly one tooth per cycle.

On a 214 or a 218, the index wheel boasts 320 teeth each of which is ten microns.

The index wheel turns 38 million times per year so since 1960, the earliest accutron, being used now for 62 years, with a battery inside all this time, has turned 2 billion, 356 million times, so it is a wonder that it’s still operational after all these years. It is made out of berilium copper.

Tags: